Euro SPF 2025

Renfrewshire - Glasgow

15 - 18 September 2025

Hosted by the Advanced Forming Research Centre. Part of the National Manufacturing Institute Scotland.

Renfrewshire - Glasgow

15 - 18 September 2025

Hosted by the Advanced Forming Research Centre. Part of the National Manufacturing Institute Scotland.

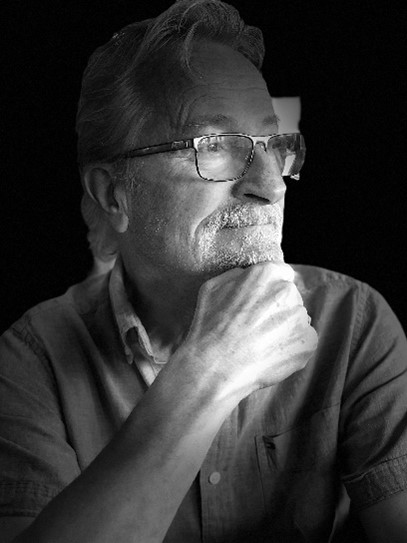

Senior Technical Advisor, Superform USA

Anthony Barnes, known as AJ, is a pioneer in the field of superplastic forming, with a distinguished career spanning over five decades. Currently serving as Senior Technical Advisor at Superform USA, AJ began his journey in 1969 at Tube Investments Research Laboratories, Hinxton Hall, where he worked as a Senior Research Engineer specializing in project appraisal.

He was part of the original Superplasticity Project Team that proposed the creation of Superform Metals Ltd., and in 1973, he became a founding Technical Director of the company. His leadership helped shape the early commercial applications of superplastic forming technology.

In 1981, Superform, in collaboration with TI and British Aluminium Research Labs, was honored with the Queen’s Award for Technology. AJ continued his pioneering work by founding Superform USA in Riverside, California, in 1985, where he served as Director and VP of Technical through 2010.

His contributions to the field earned international recognition, including a seat on the ICSAM International Advisory Board in 2003, and in 2008, the prestigious Gold Medal from the Institute of Materials, Minerals and Mining (IOM3) for lifetime achievement in developing and commercializing superplastic alloys and applications.

Although officially retired in 2010, AJ returned to Superform USA just two weeks later and continues to provide guidance and support as needed through 2025. He holds several patents, has authored numerous technical papers, and is a frequent speaker at global conferences.

Chief Portfolio Officer, High Value Manufacturing Catapult

Dr Lynne O’Hare joined the High Value Manufacturing Catapult in November 2023 as Chief Portfolio Officer, where she oversees the comprehensive portfolio of programmes at HVM Catapult and has responsibility for fostering and growing collaboration across the network.

In a career spanning more than two decades, Lynne has established herself as an innovative and systematic thinker, passionate about the future of advanced manufacturing, and about bringing people and partnerships together to drive innovation and impact.

Before joining HVM Catapult, Lynne spent seven years in senior leadership roles in the Advanced Forming Research Centre (AFRC) and National Manufacturing Institute for Scotland (NMIS), where she played a pivotal role in the foundation, development and growth of both centres from 2009.

Lynne is a Chartered Mechanical Engineer and before moving to commercial and strategic roles worked in a range of technical disciplines including computational fluid dynamics, prosthetics and hot metal forming.

Vice President of Research and Technology, Sugino

Dr. Daniel G. Sanders started his career in industry as a machinist for John Fluke Manufacturing in 1977, which led him to become an accomplished tool & die maker for many years. Since then, he studied for multiple engineering degrees, all while working full-time concurrently at Boeing for a total of 42 years. He holds a PhD in Mechanical Engineering that was completed at the University of Washington (U.W.) in 2008. He retired from Boeing as a Senior Technical Fellow in 2020 and has served as an Affiliate Professor at the U.W. M.E. Dept. for the past 12 years.

Dr. Sanders has worked to develop innovative manufacturing & materials technologies for aerospace products using methods such as friction stir welding, superplastic forming, diffusion bonding, robotics, shot peening, testing of new titanium alloys and the advancement of several emerging additive manufacturing (AM) processes. Much of his published work is related to the metallurgy & superplastic characteristics of advanced high temperature materials.

His most recent work as V.P. for Research & Technology at Sugino Machine Ltd is to adapt cavitation water jet peening (CWJP) and cavitation abrasive surface finishing (CASF) for production use. Both of these new processes can be applied as a means for cleaning & smoothing the surface of AM parts and also applying compressive residual stresses to help prevent the initiation of fatigue cracks.

As a hobby, Dr. Sanders enjoys tunneling in his hard rock gold mines located in the Cascade Mountain Range of Washington State.